Keeping the Office Safe: A Comprehensive Guide to Radiation Detection and Safety Protocols

- obilleliza2

- 5 days ago

- 4 min read

As technology evolves, the potential sources of electromagnetic radiation (EMR) and ionizing radiation in our everyday environments including offices have grown. While the levels are generally low, proactive radiation safety protocols are crucial for maintaining a healthy and secure workplace.

What Radiation Sources Are Present in Offices?

Understanding the types of radiation and their sources is the first step in setting up effective protocols. Office environments typically involve two main categories:

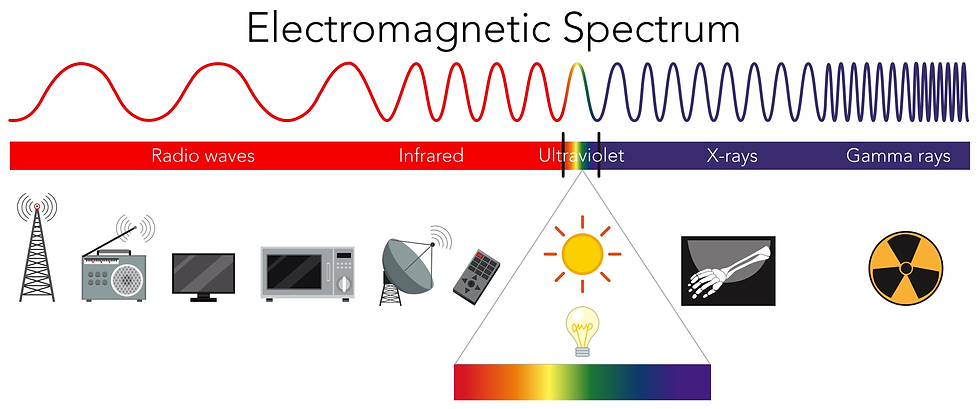

1. Non-Ionizing Radiation (EMR)

This type of radiation has lower energy and doesn't carry enough power to remove electrons from atoms (ionization).

Sources:

Wi-Fi Routers and Bluetooth Devices: Emit radiofrequency (RF) waves.

Computers, Monitors, and Smart Devices: Emit low-level EMR.

Microwave Ovens (in breakrooms): Primarily leakage of microwaves (a form of RF).

Fluorescent Lighting: Can emit trace amounts of UV light and low-frequency EMR.

2. Ionizing Radiation (Typically Low-Risk)

This is higher-energy radiation that can cause ionization, posing a greater potential health risk at high exposure levels. In most standard offices, these sources are minimal but warrant attention if specialized equipment is used.

Sources:

Natural Background Radiation: Cosmic rays and naturally occurring radioactive materials (NORMs) in building materials (like granite).

X-Ray Security Scanners: Used in high-security facilities (e.g., mailroom scanners).

Industrial Gauges: Rarely used in an office, but common in adjacent research or manufacturing facilities.

Phase 1: Office Radiation Detection and Assessment

A proper safety protocol begins with an initial survey to establish baseline radiation levels.

1. Equipment Selection for EMR Detection

For non-ionizing sources, a broadband field strength meter or EMF meter is recommended.

Key Metrics to Monitor:

Electric Field Strength: Measured in volts per meter ($V/m$).

Magnetic Field Strength: Measured in microtesla ($\mu T$) or milligauss ($mG$).

Power Density (for RF): Measured in microwatts per square centimeter ($\mu W/cm^2$).

2. Equipment Selection for Ionizing Radiation Detection

For environments where ionizing sources might be present (e.g., adjacent to medical or industrial sites), a specialized device is necessary.

Geiger Counter (Geiger-Müller Tube): The standard tool for detecting alpha, beta, and gamma radiation. Measures radiation dose rate, typically in microsieverts per hour ($\mu Sv/hr$).

Dosimeters: Personal devices worn by employees in high-risk areas (e.g., mailroom staff operating X-ray scanners) to track cumulative radiation dose.

3. Conducting the Survey

Baseline Measurements: Measure all common office areas (desks, breakrooms, meeting rooms) during normal operation.

Hotspot Identification: Pay special attention to areas near large equipment: Wi-Fi routers, server rooms, kitchen microwaves, and fluorescent light banks.

Documentation: Record the measured values, the location, the equipment type, and the date. This radiation survey report is the foundation of your safety protocol.

Phase 2: Establishing Comprehensive Safety Protocols

Based on your initial detection assessment, implement these three key protocols.

1. Administrative Controls (Policy and Training)

Exposure Limits Policy: Define maximum permissible exposure (MPE) levels for employees, referencing standards set by organizations like the International Commission on Non-Ionizing Radiation Protection (ICNIRP) and national bodies (e.g., the Occupational Safety and Health Administration - OSHA).

Employee Training: All staff must be trained on the basics of radiation safety.

Focus Areas: ALARA Principle (As Low As Reasonably Achievable), proper use of office equipment, and reporting procedures for potential safety concerns.

Scheduled Audits: Implement a schedule for periodic re-surveys (e.g., bi-annually or whenever new, major equipment is installed).

2. Engineering Controls (Physical Modifications)

These controls are designed to minimize exposure at the source.

EMR Sources:

Relocation: Move high-EMR sources (like Wi-Fi routers and printers) away from frequently occupied desks. A distance of 1-2 meters can significantly reduce exposure.

Shielding: Use approved RF shielding materials for server room walls if radiation levels are high enough to affect adjacent workspaces.

Ionizing Sources (if applicable):

Interlocks and Signage: Ensure X-ray scanners or industrial gauges are properly shielded and have safety interlocks to prevent accidental exposure. Post clear radiation warning signs.

Ventilation: Good air circulation helps disperse trace amounts of Radon a naturally occurring radioactive gas which can accumulate in basements or poorly ventilated lower floors.

3. Personal Protective Equipment (PPE) and Monitoring

For the vast majority of office workers, no PPE is needed. However, staff operating specialized equipment require specific measures.

Dosimetry Program: Any employee working with or near an ionizing radiation source should be enrolled in a personal dosimetry program, wearing a badge that tracks their cumulative exposure.

Proximity Avoidance: The simplest form of protection is distance (from the source) and time (limiting exposure duration), following the Inverse Square Law of radiation: the intensity decreases proportionally to the square of the distance from the source ($I \propto 1/d^2$).

Phase 3: Documentation and Continuous Improvement

To ensure your protocols are effective and compliant with regulations, maintain rigorous records and a plan for continuous improvement.

Safety Data Sheets (SDS): Keep records for any equipment that explicitly mentions radiation or EMR components..

Incident Log: Maintain a log to record any reported concerns, unexpected high readings, or near-misses related to radiation.

Review Cycle: Annually review the entire radiation safety protocol with management and a certified health physicist or industrial hygienist to ensure it remains current with technology and regulatory changes.

By implementing these detailed steps from initial detection to continuous monitoring your office can maintain a secure, healthy environment while maximizing operational efficiency. Prioritizing radiation safety is an investment in your employees' well-being and the longevity of your business.

While Singapore is a nuclear-free zone, understanding potential radiation risks is crucial. Our detailed guide explores these risks, outlines Singapore's safety frameworks, and highlights singaporenuclear.com as a key resource for PPE and radiation hardware for enhanced preparedness.

Comments